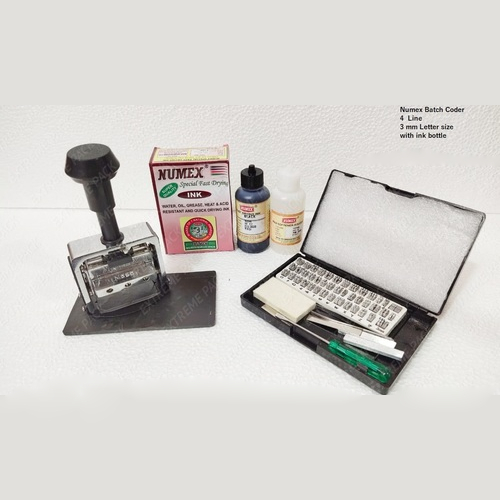

Manual Batch Coder

3000 INR/Unit

Product Details:

- Marking Speed Depend on Manual Operation

- Marking Area Up to 150 x 25 mm

- Condition New

- CNC Yes

- Cooling Mode Manual, Air Cooled

- Accuracy High (Batch coding related)

- Power Manual, No electricity required

- Click to View more

X

Manual Batch Coder Price And Quantity

- 1 Unit

- 2000.00 - 5000.00 INR/Unit

- 3000 INR/Unit

Manual Batch Coder Product Specifications

- Yes

- Depend on Manual Operation

- Up to 150 x 25 mm

- Manual, Air Cooled

- Manual, No electricity required

- New

- Approx. 300 x 250 x 200 mm

- High (Batch coding related)

Manual Batch Coder Trade Information

- 50 Unit Per Day

- 2 Days

Product Description

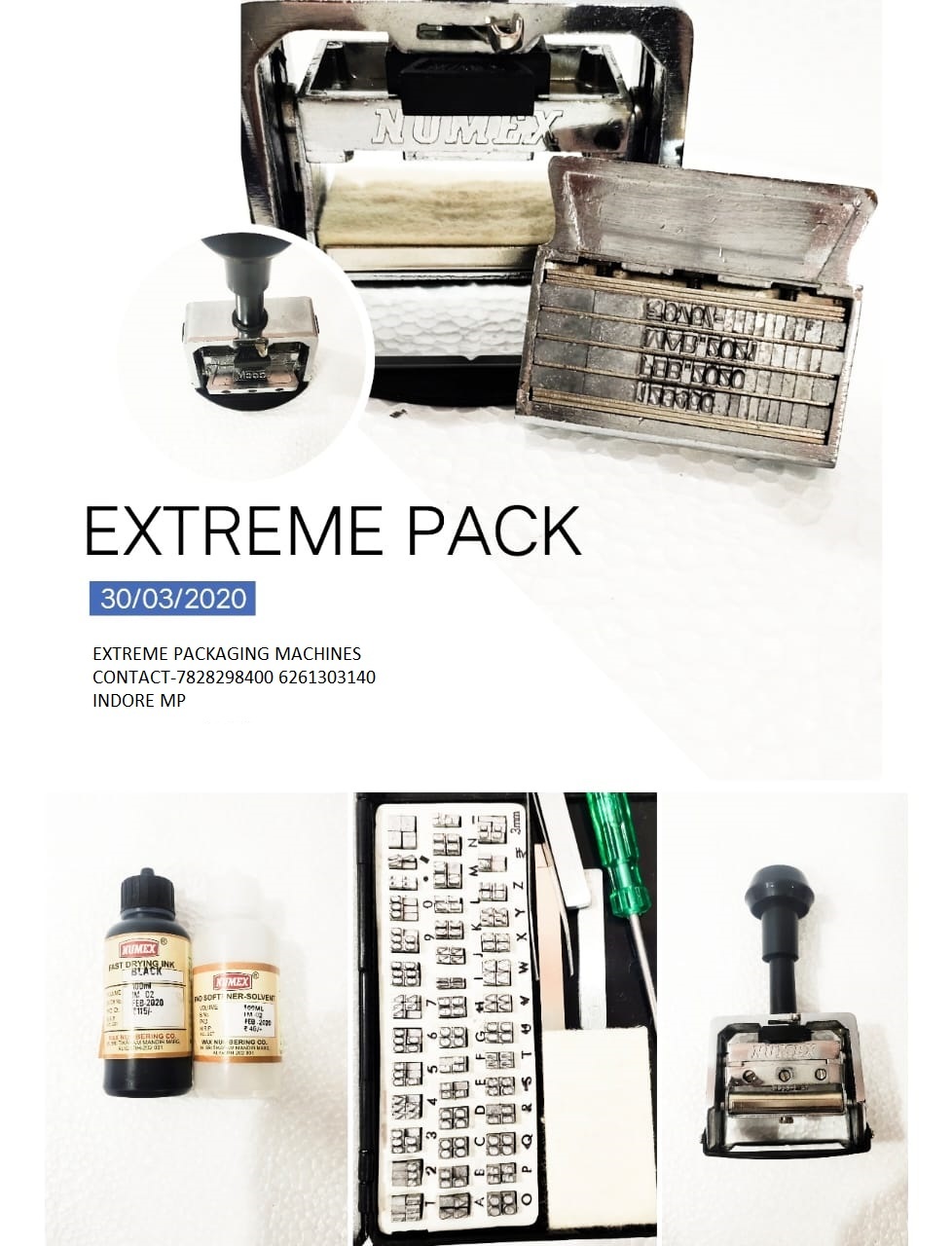

APPLICATIONS & USES

- heavy duty model for printing Batch No , Packing Date , Expiry Date Maximum retails Price , Net Weight , Quantity,Size etc.

- Printing by Indelible ink and reusable Metal letters.

- Can Print on any surface like flat ,round,curved ,bottom etc.

- Can Print on any surface like metal plastic flims polythene HDPE sacks,ceramics and glass etc.

- Can Print on amy product like bottles jars,pouchs,laminated labels & cartons tins cups etc.

- Can Print on porous and non porous surfaces 7-Can Print statutory information to meet legal requirements

3MM LETER SIZE 4LIN

METAL LETTER M555 MODEL

Versatile Coding for Multiple Packaging Types

This manual batch coder is perfectly suited for marking on cartons, labels, pouches, and bags. Its flexible marking area of up to 150 x 25 mm lets you apply essential informationsuch as batch numbers, manufacturing and expiry dates, prices, and moreacross a wide range of materials, meeting the needs of diverse industries.

Simple, Durable, and Portable Design

Constructed with a robust metal body, this hand-operated machine is built for longevity and frequent use. Weighing just 8-10 kg and featuring manual cooling, its easily portable between production sites. No electricity is needed, so you can carry out accurate batch coding operations even in remote or power-limited working environments.

FAQs of Manual Batch Coder:

Q: How is the Manual Batch Coder operated?

A: The batch coder is hand-operated using a simple mechanical process. No electricity is required for operation, making it easy to use and suitable for factories or sites without consistent power supply.Q: What types of materials and surfaces can this coder be used on?

A: It is suitable for various packaging options including cartons, labels, pouches, and bags. The robust design and compatibility with different quick-drying inks ensure clear, smudge-free codes on multiple surfaces.Q: When is it beneficial to use a manual batch coder rather than an automatic one?

A: A manual batch coder is ideal for operations where production volumes are moderate, power supply may be inconsistent, or portability is required. It offers cost-effective, reliable coding without ongoing energy expenses.Q: Where can this machine be utilized efficiently?

A: Its effective in small to medium-sized manufacturing units, packaging stations, warehouses, or any location requiring batch code marking but lacking fixed or reliable electrical infrastructure.Q: What is the general process for batch coding using this machine?

A: Simply load the suitable quick-drying ink, position your packaging material, and manually operate the coder to imprint the necessary batch, date, or price information. The marking speed depends on the users speed and workflow.Q: How does this device ensure high accuracy in marking?

A: The manual mechanism, coupled with sturdy construction and precise marking plates, delivers consistently accurate and legible batch codes on each item, reducing the risk of human error.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free