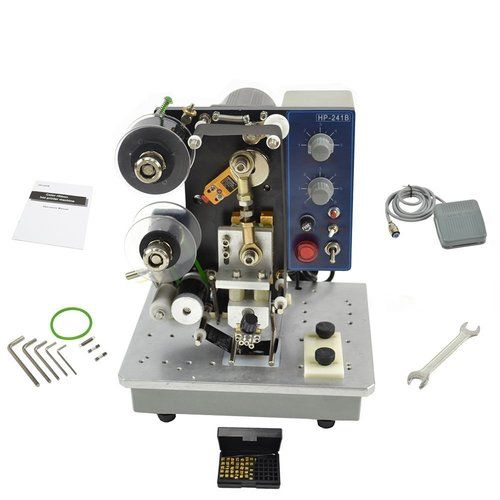

Semi Automatic Electric Coder

14500 INR/Piece

Product Details:

- Marking Speed 0-120 times/min

- Marking Area 0-50 mm

- Condition New

- Laser Type Ribbon Coding (Non-laser)

- CNC Yes

- Cooling Mode Air Cooling

- Control Software Digital Temperature Controller

- Click to View more

X

Semi Automatic Electric Coder Price And Quantity

- 14500 INR/Piece

- 1 , , Piece

Semi Automatic Electric Coder Product Specifications

- New

- Ribbon Coding (Non-laser)

- 1 mm

- 0-50 mm

- 0-120 times/min

- Digital Temperature Controller

- Air Cooling

- Yes

- 220V/50Hz, 100W

- 400 x 260 x 310 mm

Semi Automatic Electric Coder Trade Information

- 50 , , Piece Per Day

- 2 Days

- All India

Product Description

Semi-Automatic Electric Coder can take used of the hot stamp printing technologies instead of the ink printing. It is widely used to print batch code, expiry date and weight on different material like aluminum, plastic film, leather and plastic products. This coder is made under the guidance of our expert professionals by using latest technologies keeping in mind the set quality norms. Our provided Semi-Automatic Electric Coder is known for their unique features like easy to operate, modular design, light in weight and convenient maintenance.

Specification

| Condition | New |

| Brand | HP 280 |

| Model | SEMI |

| Applicable Machine Type | BATCH CODER |

| Capacity (pcs/Min) | 1 PEACE PER SECOND |

| Weight | 20 |

| Automation Grade | Semi-Automatic |

Product details

| Country of Origin | Made in India |

| Power Source | Electric |

| Automation Grade | Semi-Automatic |

| Weight | 20 Kg |

| Voltage | 240V |

| Brand | Extreme |

Effortless and Accurate Coding

Experience seamless printing with this semi-automatic electric coder, which ensures consistently accurate labeling on diverse surfaces like plastic film, paper, and aluminum foil. Its digital temperature control and hot stamp method provide sharp, smudge-free prints, catering to various industries seeking reliable and legible product markings.

Versatility for Multiple Industries

Engineered to serve food, pharmaceutical, chemical, and cosmetic sectors, this coder adapts to a wide range of packaging materials and sizes. Its flexibility and controlled operation make it a preferred tool for manufacturers, suppliers, and distributors in India who demand efficient, consistent, and high-quality coding.

FAQs of Semi Automatic Electric Coder:

Q: How does the semi-automatic electric coder operate?

A: The coder works in semi-automatic mode, where materials are placed manually and the machine hot stamps the required information using a ribbon. The digital temperature controller ensures precise heating, making operations quick and user-friendly.Q: What materials can be printed using this coder?

A: This coder is suitable for printing on plastic film, aluminum foil, labels, and paper cards, making it highly adaptable for a range of packaging requirements in diverse industries.Q: When should I use this coder instead of other marking solutions?

A: The semi-automatic electric coder is ideal for small to medium batch production where efficiency, clarity, and flexibility in material compatibility are essential. It is particularly useful when variable information like batch numbers or expiry dates needs to be printed quickly and accurately.Q: Where is this coder commonly used?

A: The coder is widely used in food processing, pharmaceutical packaging, chemical product labeling, and cosmetic industries across manufacturing, distribution, and supply chains in India.Q: What is the process for setting up and using the machine?

A: Setup involves loading the 30 mm wide ribbon, setting the required character size (2, 3, or 4 mm), adjusting the digital temperature controller, and allowing a brief heating period (12 minutes). Once warmed up, place the item and activate the print cycle to complete coding.Q: What are the benefits of using a hot stamp coding method?

A: Hot stamp coding produces durable, non-smearing prints that resist moisture and abrasion. This assures legibility and compliance, crucial for products that are distributed or stored in varying environmental conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS