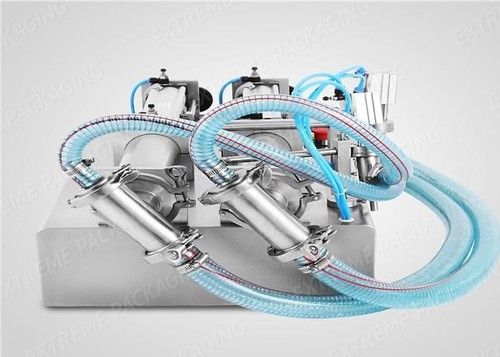

Double Nozzle Liquid Filling Machine

85000 INR/Unit

Product Details:

- Product Type Double Nozzle Liquid Filling Machine

- Material Stainless Steel (SS 304/316)

- Application Liquid filling in bottles, cosmetics, pharmaceuticals, chemicals, food industry

- Packaging Material Plastic, Glass, PET bottles

- Computerized Yes

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Click to View more

X

Double Nozzle Liquid Filling Machine Price And Quantity

- 01 Unit

- 10000.00 - 90000.00 INR/Unit

- 85000 INR/Unit

Double Nozzle Liquid Filling Machine Product Specifications

- Silver/Grey

- Stainless Steel (SS 304/316)

- Electric

- 850 x 550 x 600 mm

- 10-1000 ml per filling

- PLC Control

- 220V/50Hz

- Double Nozzle Liquid Filling Machine

- Yes

- Semi-Automatic

- Plastic, Glass, PET bottles

- High precision, anti-drip, adjustable speed

- Approx. 80 kg

- Liquid filling in bottles, cosmetics, pharmaceuticals, chemicals, food industry

Double Nozzle Liquid Filling Machine Trade Information

- 100 Unit Per Week

- 7 Days

- All India

Product Description

It is ideal semi-auto Liquid filling equipment for medicament, light industry, food, pesticide and other special industry. Adopting advanced pneumatic parts from Taiwan AIRTAC. Simple operations are the main feature of machine. The piston and cylinder are made up of 304 stainless steel and Polytetrafluorothylene (PTEF). It accords with GMP requirement. The filling range and speed are adjustable. Filling unit has function of leaking-proof, silk nuzzling-proof. Machine is able to change to multi-head, burst-proof and flood-proof filling unit according to requirement of customers.

Specification:

- Model : GC-A

- Filling Type:One nozzle

- Air supply :400L/min 0.6Mpa

- Filling range(ml) :10-100, 50-500, 100-1000ml.

- Efficiency(Bottle/ hour) : 600-1500

Product details

| Machine Type | Automatic |

| Electric Load | peston type |

| Usage/Application | Pharma |

| Power Consumption | 350 |

| Packaging Type | bottle filling type |

| Material | Stainless Steel |

| Driven Type | Hydraulic |

| Capacity | 4000 pouch per hour |

High-Precision Filling for Multiple Industries

Our double-head liquid filling machine is engineered for precise liquid dosing, delivering consistently accurate results with a 1% fill accuracy. Adaptable to a variety of applications, it is perfect for filling water, oils, syrups, shampoos, and more. The system is suitable for cosmetic, pharmaceutical, food, and chemical manufacturers requiring clean and efficient processing.

User-Friendly Operation and Easy Cleaning

With its semi-automatic PLC-based control, operators can choose between foot pedal or fully automated filling. The machines modular stainless steel design enables quick disassembly, making daily cleaning straightforward and minimizing downtime. Its 30-liter hopper and non-drip nozzles reduce mess and product waste.

FAQs of Double Nozzle Liquid Filling Machine:

Q: How does the double nozzle non-drip system benefit the filling process?

A: The double nozzle non-drip system ensures each bottle is filled precisely without spillage or leakage, preventing wastage and maintaining a clean production area. This feature is particularly advantageous when filling viscous liquids like syrups and shampoos.Q: What types of liquids and bottles are compatible with this machine?

A: This filling machine accommodates low to medium viscosity liquids, such as water, edible oils, syrups, and shampoos. It is compatible with plastic, glass, and PET bottles, making it suitable for varied packaging needs across different industries.Q: When should I use manual versus automatic operation mode?

A: Manual foot pedal mode is ideal for smaller batches or when operator control is preferred. Automatic mode is beneficial for continuous production runs, enabling the machine to fill bottles consistently without manual intervention, thus improving efficiency.Q: What is the process for cleaning the filling machine?

A: The machine is designed for easy disassembly. Components in contact with the liquid can be quickly removed, cleaned, and reassembled. This makes regular sanitation simple, supporting compliance with hygiene standards, especially in the food and pharmaceutical industries.Q: Where is this machine commonly used?

A: This liquid filling machine is widely deployed in bottling operations within the cosmetics, pharmaceutical, chemical, and food industries across India. Its versatility ensures smooth integration into diverse production lines.Q: How do I benefit from the PLC control system?

A: The integrated PLC control system allows precise adjustment of fill volumes and speed, ensuring consistent results and easy adaptation to different bottle sizes and liquids, while reducing the risk of operator error.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS